In a refractive index measurement, the wavelength of the light beam matters because of the effect of dispersion on the properties of waves in a medium (known as dispersion relation). Almost all substances have different refractive indices that also differ depending on the wavelength used. This dispersion relation can be calculated as follows.

We know that the speed of light in a medium is:

v = c/n

Where:

n is the index of refraction

c is the speed of light in a vacuum (or air)

v is the speed of light in the media

Similarly, the wavelength in the same medium is:

λ = λ0/n

where λ0 is the wavelength of that light in a vacuum (or air).

Therefore, the refractive index (n) is inversely proportional to the wavelength and also to the speed of light. This means the greater the wavelength, the lower the refractive index. This relationship is represented by the equation:

v(λ) = c/n(λ)

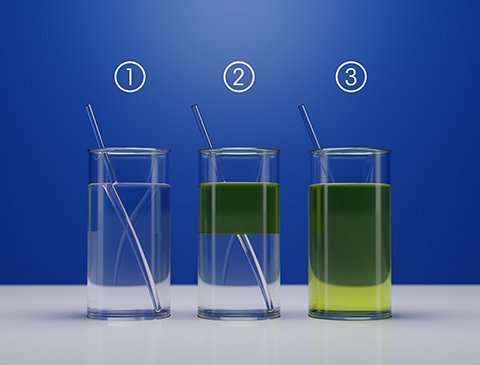

However, for industrial applications where refractive index measurement is required, it is necessary to have a defined, precise wavelength to allow the refractive index measurement of different samples to be analyzed under the same conditions for quality control.

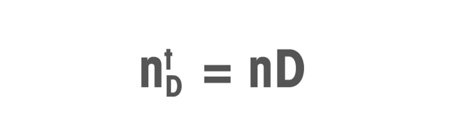

To generate a defined wavelength, refractometers most often use the sodium D-line, which corresponds to 589.3 nm. Due to the fact that it is a widely available, reliable and stable light source, the sodium D-line has long been used in the study of refractive index.